Twin Head Blown Film Equipment

Informations de base

Modèle: DM

Description du produit

Twin Head Blown Film Equipment

Two Die Heads, Single Screw Film Largeur de 100 ~ 800mm Diamètre de l'extrudeuse: 45mm ~ 75mm Matériau: HDPE, LDPE Sortie: 30 ~ 140 kg / h

Produit possible de Twin Head Blown Film Equipment

|

| Shopping bag T-shirt bag Bottom sealed flat bag Supermarket bag |

Twin Head Blown Film Equipment - Conçu pour l'industrie de l'emballage flexible

| |

|

Polystar designs and customizes this type of Twin Head Blown Film Equipment with different screw diameter and roller width depending on the customers’ requirement. Available in screw diameter of 55mm, 60mm, 65mm and 75mm and film width from 400mm up to 1000mm on each winder. The Twin Head Blown Film Equipment also allows producers to switch between HDPE and LDPE production as well as producing different film width on the same machine on each winder simultaneously.

| |

|

|

|

A special screw design for Twin Head Blown Film Equipment is used to provide good mixing and stable output for both HDPE and LDPE material. Bimetallic treatment is applied to process a higher percentage of recycled material and CaCO3 compound. Polystar Twin Head Blown Film Equipment uses Siemens/ABB energy saving motors for the extruders which can reduce energy consumption up to 5%.

| |

| |

POLYSTAR Twin Head Blown Film Equipment dans le monde

| POLYSTAR has already installed more than 250 sets of Twin Head Blown Film Equipment in Mexico and throughout Central and South America. |  |

| POLYSTAR has installed its machines in more than twelve film producers within the last ten months in Ho Chi Minh and Hanoi. “POLYSTAR’s machine has been nothing but amazing since day one,” said the director of one of the Ho Chi Minh based bag producers, now producing on an average of 75~100kg/hr of high quality HDPE film rolls in different calibers (sizes) for T-shirt bags with POLYSTAR’s Twin Head Blown Film Equipment. |  |

| Twin Head Blown Film Equipment is frequently purchased equipment for producers in T-shirt bags and shopping bags industry. As a film producer with decades of experience, this company has built up a strong supply chain to supply perforated grocery bags and T-shirt bags to most of the grocery shops and supermarkets in Sri Lanka. |

|

Exposition POLYSTAR avec équipement de film soufflé Twin Head

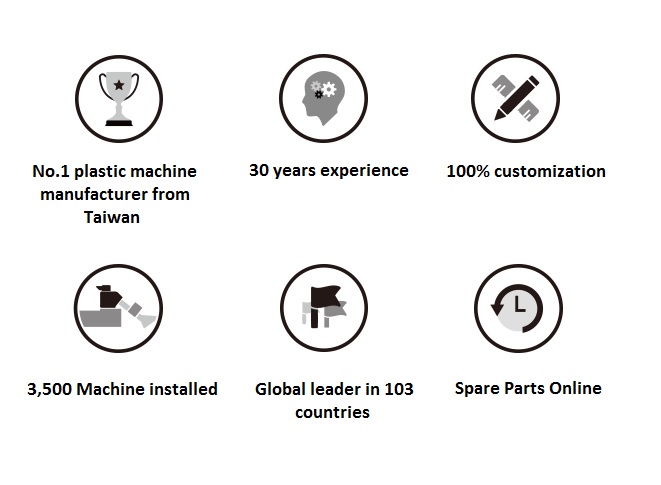

Pourquoi POLYSTAR Twin Head Blown Film Equipment

|

High quality film roll

High precision die head and cooling air ring of

Twin Head Blown Film Equipment provide

good film thickness control and resistance.

|

|

Manufacturing with Precision

CE certified Twin Head Blown Film Equipment

with total quality control

Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency Strong research and design team |

|

Service and Communication Overseas Twin Head Blown Film Equipment installation service and training are available |

Our Experience, Your Advantage

| |

Site web de POLYSTAR:

Groupes de Produits : Machine à film soufflé > Machine à film soufflé à deux têtes

Premium Related Products