Mini processus d'extrusion pour les plastiques

Informations de base

Modèle: MB

Description du produit

Mini processus d'extrusion pour les plastiques

Simple en conception, productif et flexible

Le procédé Mini Extrusion For Plastics offre une bonne solution pour un film économique mais de bonne qualité. Convient aux produits d'emballage en général tels que des sacs de t-shirt, des sacs de supermarché, des sacs plats et bien d'autres.

|

Since 1988, Polystar has produced nearly 1,000 sets of Mini Extrusion Process For Plastics that has helped customers produce around the world. |

| Film width of Mini Extrusion Process For Plastics available from 150mm to 800mm (5 to 31 inch) and can be customized depending on customer's requirement, suitable for both HDPE and LDPE film. In-line printer can be added for logo printing. |  |

|

Mini Extrusion Process For Plastics is a simple and flexible machine that can produce HDPE or LDPE, by simply changing the die head and air ring. |

|

Polystar's Mini Extrusion Process For Plastics is popular for starters who look to start the film production business with an economic but reliable machine. It is also widely used by industrial leaders who produce bags in large quantity. |

|

Mini processus d'extrusion pour les plastiques dans l'usine de client

|

In Siberia, Russia, Polystar installed the third set of Mini tpye blown film machine in customer's factory since June 2014.

The producer is using Polystar Mini Extrusion Process For Plastics for producing films for garbage bag. In 6 month, the raw material cost has been decreasing significantly. |

|

In June, Polystar installed another two sets of Mini Extrusion Process For Plastics in Dallas, USA.

|

|

|

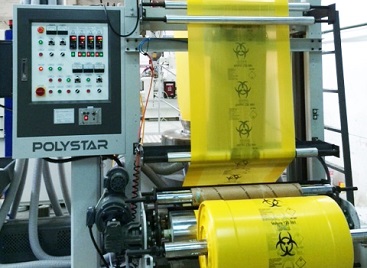

In Romania, Polystar installed a Mini Extrusion Process For Plastics to make films for making medical waste plastic bags.On Mini Extrusion Process For Plastics , we install an inline logo printer to print the ''infectious waste'' warning logo on the film for medical waste plastic. The printing plate can be changed to any picture that customer requests. The printing color can be changed as well. Adding this inline logo printing unit on Mini Extrusion Process For Plastics is a good idea for saving the space for installing another printing machine in the factory. |

Pourquoi le procédé POLYSTAR Mini Extrusion pour les plastiques

|

High quality film roll

High precision die head and cooling air ring of

Mini Extrusion Process For Plastics provide

good film thickness control and resistance.

|

|

Manufacturing with Precision

CE certified Mini Extrusion Process For Plastics

with total quality control

Adopts the latest design and manufacturing of screw

and barrel to achieve maximum efficiency

Strong research and design team |

|

Service and Communication Overseas Mini Extrusion Process For Plastics installation service and training are available |

Our Experience, Your Advantage

| |

Site web de POLYSTAR:

Groupes de Produits : Machine à film soufflé > Mini machine à film soufflé

Premium Related Products