Machine à déchiqueteuses à recyclage

Informations de base

Modèle: Repro-Flex

Description du produit

Machine de déchiqueteuse de recyclage de TAIWAN Technologie directe en une étape avec coupe + extrusion + granulation Très facile à installer, à faire et à effectuer la maintenance Récupération interne à sa meilleure sortie: 100-1200 kg / h

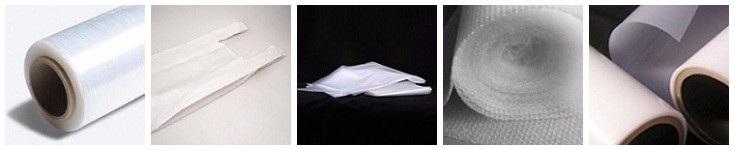

| Recycling Materials of Recycling shredders machine |

|

| PE/PP Film Roll Bags Film Scraps Bubble Film Film Sheet |

|

| Raffia Nonwoven Flakes Strech Film Garbage Bag Washed Flake |

In-house Recycling at its Best: Recycling shredders machine for Post-Industrial Waste | ||

| ||

| ||

| Blown and Cast Film Producers | Raffia & Woven | Rigid Regrind |

PE, PP film rolls, edge trim waste from blown film process , T-shirt bags cut-offs from bag making process can be recycled in a simple process with Recycling shredders machine. The high-quality, uniformed-sized pellets made by Recycling shredders machine are almost like virgin material which can be put directly back to film production line. |

In-house waste generated from the production of PP woven bags, non-woven, jumbo bags, PP raffia, PP woven sacks and tapes. The PP pellets recycled by Recycling shredders machine can be reused (100%) for production, in most cases in circular weaving looms and tapelines. | Pre-crushed, heavy rigid regrind scraps such as bottles, pipes, containers and lumps in the form of granules can recycled by Recycling shredders machine. Applicable materials are mailny HDPE, LDPE, PP, PA, PC, PU, ABS and others. |

| Simple in Design, Flexible in Operation: Recycling shredders machine | |

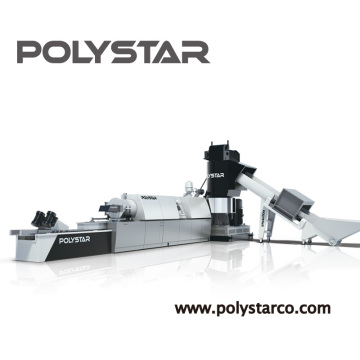

POLYSTAR’s Repro-Flex Recycling shredders machine is designed for reprocessing polyethylene (HDPE, LDPE, LLDPE) and polypropylene (PP) flexible packaging material, printed and non-printed. This cutter integrated pelletizing system of Recycling shredders machine eliminates the need of pre-cutting material, requiring less space and energy consumption while producing high-quality pellets at a highly productive rate. | |

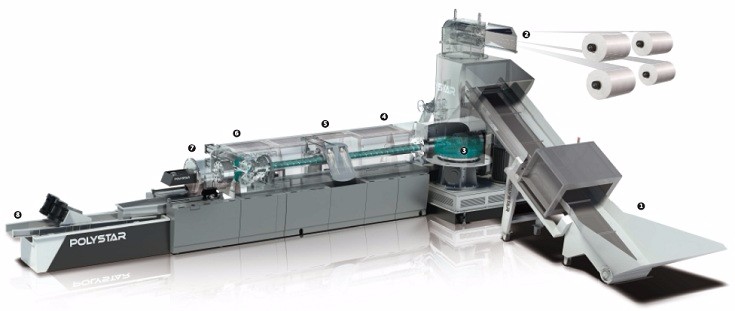

How POLYSTAR Repro-Flex Recycling shredders machine works | |

| |

|

1 & 2 - Feeding Feeding of scraps is easy, flexible and autimatically controlled. Film-on rolls can be fed with nip roller feeder.

The conveyor of Recycling shredders machine is installed with sesotec metal detector made in Germany. |

|

3 - Cutting & Compacting Very fast and stable feeding from the compactor directly into the extruder | |

|

4 - Additive feeder Color master batch and CaCO3 compunds (in pellet form) can be added during the recycling process | |

|

5 - Double degassing Able to process both printed and non-printed material | |

|

6 - Filtration Filter with dual channel system for non-stop operation and reduces machine down time | |

|

7 - Die face pelletizing Produces high quality plastic pellets for reprocessing | |

|

BOPP and Stretch Film Recycler - USA

BOPP, stretch film scraps and film on-roll can be turned into high quality pellets for reprocessing. POLYSTAR's advanced cutter-compactor system of Recycling shredders machine can process material that is typically more difficult to recycle due to its special property, such as printed BOPP and stretch film that one normally faces problem with the traditional Recycling shredders machine. |

|

|

PP Woven Producers - Saudi Arabia

In-house waste generated from the production of PP woven bags, non-woven, jumbo bags, PP raffia, PP woven sacks and tapes. The recycled PP pellets from Recycling shredders machine can be reused (100%) for production. In most cases in circular weaving looms and tapelines. |

|

|

Recycling Center - Nigeria

Professional recyclers who collect both post-consumer and post-industrial waste. The pellets quality of Recycling shredders machine can be improved by direct dosing of masterbatch and additives. |

|

POLYSTAR Exposition avec machine à broyer recyclage

Pourquoi les machines à broyer recyclage POLYSTAR

Groupes de Produits : Machine de recyclage de plastique > Machine de recyclage fortement imprimée