Équipement de recyclage du refroidissement par air

Informations de base

Modèle: RP

Description du produit

Équipement de recyclage du refroidissement par air

La machine à recycler économisant de l'espace

|

|

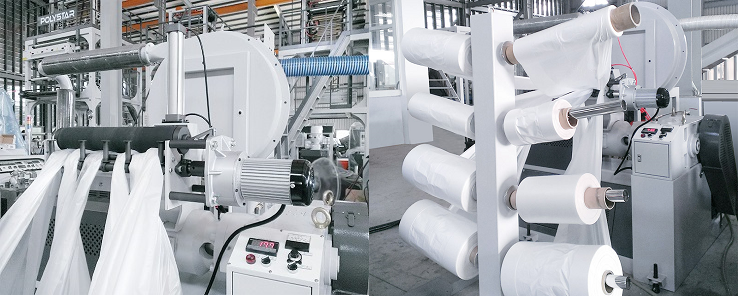

Air cooling recycling equipment is specially designed for blown film and cast film producers. Air cooling recycling equipment can effectively recycle HDPE, LDPE, LLDPE film scraps (mono and multi-layer), start-up or changeover film rolls (film-on-roll), edge-trim waste, T-shirt bag bundles (cut- offs) from in-house production. lightly-printed film can also be recycled into high quality, uniformed pellets by Air cooling recycling equipment .

Air cooling recycling equipment has an average output of 30~80kg per hour, 800~1000kg per day. Through the nip roll feeder, the machine can process multiple film rolls simultaneously. T-shirt bag bundles (cut-offs) from bag making process can also be thrown directly into Air cooling recycling equipment without the need for pre-crushing.

|

|

|

Air cooling recycling equipment does not require any water consumption and takes up very little space, it can fit right next to or in between blown film machines. The pellets produced by the hot die face pelletizer are 100% dry and can be put directly back into the production line for immediate reprocessing. Air cooling recycling equipment is highly recommended for packaging film producers of different types of film and bags.

|

|

|

The compact design of the recycling machine is ideal for producers with limited factory space. Air cooling recycling equipment dimension (length x width x height) is 2.5M x 2.5M x 2 M. It is extremely compact and user-friendly, and does not require any installation (ready-to use) upon Air cooling recycling equipment arrival.

|

Installation du client pour l'équipement de recyclage du refroidissement par air

|

A Japanese group installed an Air cooling recycling equipment from Polystar to recycle diaper film in Surabaya, Indonesia. The Japanese owned company is the producer of diaper and sanitary napkin. The factory in Surabaya is set up for producing the film for diaper and sanitary napkin. During production, they have some films with defected printing on the surface, the producer decided to invest a diaper recycling machine to recycle this post-industrial waste from their own factory. |

|

Polystar has sold the 100 th Air cooling recycling equipment to the film manufacturer in Azerbaijan. The mini plastic recycling system was launched in 2008 as an affordable, compact machine to complement the established, high output model HNT-V at Polystar. Since its launch, the air pelletizing line has been sold to film manufacturers worldwide. |

POLYSTAR Exhbition avec équipement de recyclage du refroidissement par air

Pourquoi POLYSTAR Équipement de recyclage par refroidissement par air

|

High quality recycled pellets

Up to 100% reusability back into your production line. Post-industrial waste generated from production of film, raffia and injection regrind can be recycled efficiently by Air cooling recycling equipment and put right back into your production lines. Meaning less amount of new (raw) material needs to be used in your production.

|

|

Manufacturing with Precision

CE certified Air cooling recycling equipment

with total quality control

Adopts the latest design and manufacturing of screw and barrel to achieve maximum efficiency Strong research and design team |

|

Service and Communication Overseas Air cooling recycling equipment installation service and training are available |

Our Experience, Your Advantage

| |

Site web de POLYSTAR:

Groupes de Produits : Machine de recyclage de plastique > Machine de recyclage refroidie à l'air

Premium Related Products